How to make a moonshine still from a flask: tips. How to make a moonshine still from a flask with your own hands How to make a moonshine still from a flask

For a Russian peasant, the invention of a moonshine still from a flask, and even with his own hands, is one of the best activities. Moreover, if you consider purchasing moonshine distillate to be an unfairly expensive undertaking, this article will tell you about all the intricacies of such a matter. A device made from a milk flask for moonshine brewing is a very acceptable option, both in terms of budget and in terms of its capacity.

Why milk can?

As a vessel for mash and distillation, an aluminum milk can is better suited than many analogues. The best option is only a frying pan, but thirty liters will not fit in it. The can itself can be of different capacities - from ten to hundreds of liters, and is inexpensive, besides, many of us have a lot of such containers lying around at our dachas. The main thing is the acceptable condition of the vessel.

It’s easy to make a moonshine still from a flask with your own hands, especially since ordinary aluminum cans are very convenient to use - a wide neck, a tight lid with a special lock and a well-known shape. Namely, milk cans have a rubber gasket on the lids for maximum tightness. The flask can withstand high temperatures quite well, except that the rubber gasket on the lid will have to be replaced with a silicone one, which can be cut from any hose.

When asking the question “How to make a moonshine still?”, you don’t need to reshape the can at all, the changes will be minimal. It is necessary to drill a hole in the lid, up to two centimeters in diameter, to allow steam to escape through the pipe to the steamer and the refrigerator. The diameter depends on the hose or tube that will be attached to the hole. If you are a gourmet gourmet and decide to attach a rectification column, you will have to make the hole wider. The column adapter has a slightly larger diameter, and a clamp clamp secures the structure. The fittings are secured with tight-fitting nuts and silicone gaskets. You can make the carving yourself, and the necessary parts can be found among the old trash in the garage or at the same dacha.

In the flask, you can also make a second hole in the lid, or in the upper part of the can, intended for a thermometer - a drill with a diameter of 5 millimeters will do. A metal tube with a diameter of 5 mm and a length of about fifty is inserted into the hole. It is important that the tube is made of stainless steel. The option with a sleeve is also suitable.

The milk can is also good because it is suitable for any moonshine equipment for regular production. Only the units need to be taken in advance so that the holes and tubes match perfectly.

Safer with valve

It is better to install a safety valve on a home-made moonshine still. The device is also attached to the lid with threads or sealant. A valve from a pressure cooker or multicooker is perfect, and it won’t be difficult to purchase at the nearest market. Given its significant role, the price of the valve is very affordable. The can closes tightly, and if the tube becomes clogged, the consequences can be dire. The valve will not allow this.

Drain valve and steam generator

It is advisable to install a tap for draining spent mash on containers of more than twenty to thirty liters, because a can with a smaller volume and two side handles is easy to empty and fill with new material, and then put back on the fire. The quality of moonshine will delight you.

The final stage of turning a milk flask into a part of a moonshine still is a steam generator, or rather, installing a fitting for it. Another hole is drilled two or three centimeters from the bottom of the can, into which the fitting is screwed. The outer side should have a thread to which the steam line will be connected, and the inner side should have a bubbler or a long spiral running from the wall to the center of the bottom of the flask. The steam generator system must be made of copper or stainless steel. The diameter of the hole and tube should not exceed 10-12 mm.

Electric heater

If gas, an electric stove or a stove in the country are not suitable for you, the milk can can be equipped with an electric heater. For this purpose, you can use boiler or other heating elements in the amount of two pieces, installing them at the bottom of the flask. The power of each should be one and a half kilowatts. To do this, you will need to drill several holes at the bottom of the can different sides if you want to use two heating devices. Accordingly, you don’t need to drill that much for one heating element.

FUM tape or heat-resistant sealant, special silicone, etc. will help achieve complete tightness. Of course, the heating elements must be secured with nuts on the outside. The connection wire must have a cross-section of 2.5 centimeters. If possible, install a voltage regulator or uninterruptible power supply, rheostat. The fact is that the electric heater must operate in two modes - “fast heating” and “moderate distillation”. Of course, for a capacity of more than thirty liters, heating elements with a power of one and a half kilowatts will not be enough - the installation of more powerful equipment is necessary.

What material to choose a flask from?

Milk flasks are available in two metals: stainless steel and aluminum. Aluminum cans are produced in the CIS countries and China. People's Republic. Stainless steel vessels can be found in Western Europe, and again in China.

If you are not limited by budget, buy a stainless steel flask - it is cheaper in China, but Europe has no equal in quality. However, Chinese goods are not always bad, and the flasks have not yet failed. However, when ordering Chinese products via the Internet, you need to be careful - if the price for a new can is amazing in its democracy, refuse to buy - there is clearly a catch.

Aluminum cans are cheaper, and they are produced in our homeland. Each of us knows that such a flask is durable, strong, not subject to corrosion, and will “outlive everyone.” However, many medical experts believe that aluminum is harmful to health. In this case, it is not so much the metal that is harmful as the reaction of aluminum with fusel oils, resin and methanol.

Nevertheless, there are millions of such units in Russia today, and about poisoning, and even more so, deaths The world does not know about alcohol made from aluminum.

You can make a moonshine still from a flask with your own hands within one day, which is quite acceptable. If you want more innovations in the form of a thermostat, thermometer, electric heater and other benefits of civilization, the process may take a little longer, because all the details still need to be found and made.

Attention, TODAY only!

Large cans, which are mainly used for transporting and storing milk, drinking water, other liquids are ideal for use in home production alcoholic drinks. Firstly, the container is convenient for making mash. Secondly, a moonshine still made from a milk can is the most common, easy to install and use, highly efficient option for distilling strong distillate.

Preparation

The can can be made of stainless steel or aluminum alloy. The product is initially intended for use in the food industry, therefore, in its manufacture, a material is used that does not oxidize upon contact with drinking liquids or food products. However, stainless steel containers are more suitable for moonshine brewing. Standard volume? 25-38 l.

An important factor for turning a milk can into a still is the presence of a standard clamp that ensures reliable sealing of the lid. It is important that the lid is original and not unscrewed from another can. There is practically no need to modify it. It is enough to drill small holes for the pipeline and thermometer.

To make a moonshine still, in addition to a milk can, you will need:

- copper tube 1.5 m long, 12 mm in diameter;

- metal-plastic pipe 25 cm long, 10.5 cm in diameter;

- flexible hoses for supplying/discharging running water to the condenser body. The diameter of the hoses can be 4-12 mm. The length is calculated based on the operating conditions of the moonshine still. On average, you will need 2-4 m of hoses (silicone pipes);

- sheet metal

Tools:

- drill;

- hacksaw for metal;

- spanners;

- scissors;

- pliers;

- stationery knife.

Fasteners:

- fittings? 3 pcs.;

- fitting? 8-10 pcs.

In addition, to seal the functional components of the device, you will need epoxy resin (300 g) and superglue.

First stage of work? marking and drilling a hole on the can to connect the steam outlet tube. Markings are also made on the condenser body in order to connect hoses to it for running water, which will cool the coil.

Making a refrigerator

Coil? an important part in a moonshine still. It is to be made from a straight copper tube,  turning it into a spiral by curling it. To do this you need some kind of solid cylindrical base. IN

turning it into a spiral by curling it. To do this you need some kind of solid cylindrical base. IN

At home, glass beer and wine bottles are most often used as braids.

To begin with, the tube is covered with sand so that it does not flatten during the process of winding onto the mandrel. The ends of the pipe are plugged with choppers made of crumpled paper. Only the middle part of the copper tube is curled into a spiral, leaving straight sections at both ends.

The refrigerator body is made from a piece of metal-plastic pipe. The length of the body should be such that the coil fits in it, plus 3 cm on each edge for sealing.

Next, fittings are pressed into the capacitor body according to pre-made markings. The fitting heated over the fire is pressed into the pipe, and the charred areas are cleaned. The connection holes are degreased, and the inlet and outlet fittings are glued in with superglue.

The plugs on opposite sides of the capacitor are covered with tin. To do this, you need to cut out 2 identical circles with a diameter equal to the diameter of the refrigerator body. In the center of each circle, make holes for the entry and exit of the coil.

The coil is placed inside the housing and secured to the plastic from the inside with superglue. Tin plugs are inserted at the ends. The gaps remaining between the body and the plugs are sealed with paper and superglue.

The refrigerator of the moonshine still is sealed using epoxy resin and dry silver. The resin is mixed with the hardener according to the instructions until the consistency of thick sour cream is obtained. To make the compound thicker, dry paint is added to it.

The refrigerator body is placed in a vertical position and a thick layer of epoxy resin and silver is poured onto the end with the plug. Leave for 12-24 hours to harden. Repeat the procedure on the opposite end of the body. The sealing and fastening of the fittings will need to be done with the same compound.

Manufacturing of steam chamber (reflux condenser)

To make a steam sump, you need to take any glass jar with a screw-on  metal lid. In the center of the cover, markings are made for the holes into which fittings for pipes, inlet and outlet steam will be installed.

metal lid. In the center of the cover, markings are made for the holes into which fittings for pipes, inlet and outlet steam will be installed.

The holes are cut with a stationery knife. Now you need to wrap a little fluoroplastic tape around the threads of the fittings, insert them into the holes on the cover and tighten the nuts. All that remains is to connect the adapter tubes to the steamer, which, when assembling the moonshine still, will connect it to the still and the condenser. What is the optimal length of connecting tubes? 25 cm.

Assembling a moonshine still from a milk can

The functional components of a homemade device for distilling moonshine are ready. All that remains is to mount the system according to the standard scheme, connecting all the parts together.

One edge of the pipe for removing steam from the distillation cube is wrapped with fluoroplastic tape. Insert it into the hole in the top of the milk can. From the inside of the container, the tube is screwed tightly with a nut. The opposite end of the outlet pipe is secured to the lid of the steam tank in the same way. The reflux condenser is connected to the condenser using an adapter pipe in the same way.

The moonshine still is almost ready for use. All that remains is to wash it from the inside. To do this, pour water (no more than 10 liters) into the can and place the device on high heat. When the water boils, the flame is reduced, but not extinguished. The water in the moonshine still will need to boil for several hours.

After cleaning, the device will be completely ready for use. You can pour in the mash and start distilling moonshine using the classic method.

Designing a device for the production of moonshine is quite an exciting activity. According to experts, earlier, when high-quality stainless steel was a scarce material, moonshine brewing devices were mainly made from aluminum milk cans. This design, due to its accessibility and simplicity, is still relevant today. Judging by numerous reviews, it is not difficult to make a moonshine still from a flask with your own hands. To do this, you will need a base in the form of an aluminum food can and some additional parts. You will find information on how to make a moonshine still from a flask in this article.

Acquaintance

From the flask is a special distillation system, the distillation cube in which has become a large container. The cube can be made of stainless steel or aluminum. According to experts, the main advantage of a moonshine still made from a flask is its low cost: the manufacturing process is possible without significant financial investments. In addition, food flasks have large volumes, namely from 25 to 40 liters, due to which the system has significant power. An important fact is that working with aluminum is easy, which cannot be said about stainless steel.

About the device

Due to the fact that the moonshine still from a flask is a homemade device, it has enough simple design. A home distiller is represented by a flask tank, hoses and a special cooling device, which is accordingly more often called a refrigerator. Additionally, some home craftsmen equip a homemade moonshine still from a flask with a cleaning device - a steamer. With it, judging by numerous reviews, the distillate is of much better quality.

Operating principle

Before making a moonshine still from a flask with your own hands, you should get an idea of how the design should work. The final product is obtained from mash, which is subjected to a heating procedure. Thus, the evaporation of alcohols, water, fusel oils and other impurities occurs. The resulting steam then passes through the distillation system. Its condensation is carried out in the refrigerator. There it cools and turns into a liquid state. If the device is provided with a steam trap, then the impurities will settle in it, and the product itself will be non-toxic. Read more about how to assemble a moonshine still from an aluminum flask below.

Where to begin?

To make a moonshine still from a flask, you must first prepare a distillation cube. Since the milk can is not initially suitable for making moonshine, the master will have to equip it with two holes. One is made in the lid, the second in the wall at the top.

Its diameter should not exceed 5 cm. Before this, the drilling sites are marked with a pencil and the diameter of the tubes is measured so that the holes do not turn out to be larger than necessary. A tube connecting the flask to the general distillation system will then be inserted into one hole, and a thermometer will be mounted into the other.

Second step

Very often, beginners wonder how to seal the lid of a flask for a moonshine still? This aspect is very important, since alcohol vapors will escape from a poorly sealed can, which will negatively affect the volume of already finished products. You can seal the structure after the holes for the hose and temperature sensor are ready. Special rubber layers are provided for food tanks. When converting such a container into a moonshine still, home craftsmen remove this gum and wrap it with FUM tape. Afterwards the product is placed in a container with water and boiled. Afterwards the layer is installed back. At the connection points of the hoses and thermometer, it is more advisable to use silicone gaskets, which are tightened with nuts. Experts recommend excluding rubber, as it will begin to melt under the influence of high temperatures, and the alcohol will have a specific aroma. In the absence of silicone, problem areas It's best to coat it with dough. If it accidentally gets into the drink, then the distiller does not have to worry about its quality.

Completion of work

At this stage, the craftsman needs to connect the hose from the tank to the cooling device. It can be made from a plastic water pipe, both ends of which must be plugged with two plugs.

This should give you two lids. Make two holes in each using a soldering iron or drill. One large one is for the pipe coming from the flask, the second - half an inch - for the fitting. Installation is carried out using special couplings. Cold water will flow into the device through a small hole. Next, the caps are screwed tightly onto the pipe and carefully sealed. Due to the fact that during the distillation process strong pressure is generated inside the refrigerator, the plugs, as some artisans claim, can fly off. To prevent this, experts advise fastening them with plastic clamps. Before attaching the second cover, a small hole is drilled in the side of the refrigerator for a bolt. It is clamped with nuts. It is important that there is a silicone gasket on the inside, the purpose of which is to prevent leakage cold water from the refrigerator. A hook can be mounted on the outside of the bolt, through which the entire structure will be attached. At the outlet, a thick tube from the common line is connected to a silicone hose. A distillate will come out of it.

About heating methods

Judging by the reviews, most moonshiners use gas stoves to heat their mash. According to experts, this method is considered not the best.

The fact is that the slop in the container can burn. To prevent this from happening, it is better to use two heating elements with a power of 1.5 kW each. Before distilling moonshine using electricity, home handyman you will have to adapt the tank. It is necessary to install heating elements into the flask. For this purpose, two holes are made in the container on both sides (if the heating element is U-shaped). If it is spiral-shaped, you can limit yourself to one hole with a large diameter. Heaters are sealed using FUM tape, thermal putty and nuts. The heating elements are connected to a cable, the cross-section of which must be at least 25 mm, and then to a rheostat or electronic unit. If the tank capacity exceeds 30 liters, then, according to the owners, the power of 1.5 kW heating elements will not be enough. The optimal indicator is 3 kW.

About the dry wig

In a classic moonshine still, the presence of any additional devices is not provided. Judging by the reviews, the drink with fusel oils has an unpleasant taste. You can tell that a product contains harmful impurities by its smell. To ensure that there are no toxic impurities in the moonshine, the distillation structure should be additionally equipped with a cleaning device - a reflux condenser. The dry steamer is used as a sump. You can make it from a one and a half liter glass jar. It is important that it has a tin lid with a thread. You need to make two holes in the lid using a wood drill.

Then two copper or brass fittings are inserted into the sump. They come with nuts and rubber washers. Copper car tubes are suitable for a homemade dry steamer. They need to be inserted into the lid so that one is 50 mm longer than the other. One tube connects the reflux condenser to the distillation flask, the second to the refrigerator.

About the drain tap

If the moonshine device is made from a tank with a capacity of no more than 25 liters, then it is not necessary to equip the structure. To drain the mash, simply remove the product from the gas stove, remove the lid and tilt the tank. A wide neck will be enough to remove the stillage and then wash the container. If the flask is designed for 40 liters, then you cannot do without a special device for draining. You can purchase it at any hardware store in the plumbing department.

In Soviet times, when high-quality stainless steel was in short supply, probably every second moonshine still was made on the basis of an aluminum flask for food products.

Nowadays, this design remains relevant due to its simplicity and accessibility. To understand what a moonshine still from a flask is, what its design and operating principle are, as well as how to make such a device with your own hands at home, you need to familiarize yourself with the issue in more detail.

A moonshine still from a flask is a distillation system that uses a large aluminum food-grade container, such as a milking can, as a distillation system, and such units are easy to make with your own hands due to the pliability of the material.

The main advantage of the flask-based design is the reduction in cost, the greater power of the system due to the large volume of the base container, mainly 40 and 25 liters, as well as the already mentioned ease of processing aluminum.

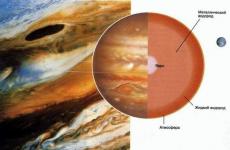

Design and principles of operation

Since the design based on a flask is homemade, the design of a moonshine still based on it is often quite simple. Basically, these are homemade ones, consisting of a tank-flask, hoses and a refrigerator; the model can also be improved with additional cleaning products in the form of a steamer and/or.

Such seemingly simple units, in the absence of more serious elements responsible for cleaning, such as a drawer or a reflux condenser, will significantly increase the quality of the distillate. In addition, the unit can be equipped to help monitor the quality of the product directly during the distillation process.

The operating principle of a moonshine still from a flask is the embodiment of the distillation process.

- Under the influence of heat, alcohol, water, fusel oils and other impurities evaporate from the mash.

- Next, steam consisting of their mixture, or at the very in a simple way After distillation, it immediately goes into the refrigerator and condenses, but then the moonshine will be of low quality, or it will first end up in a steamer and/or bubbler, where some of the impurities settle.

- It is then cooled to a liquid state.

In the second case, the passage of steam through the air layer in the steam tank leads to weaker cleaning than when passing through the water layer of the bubbler, which must be taken into account when calculating additional filtration means in the system.

How to make a moonshine still from a 25 or 40 liter flask with your own hands

Units based on such containers are most often ordinary household distillers, but there may be exceptions. Let's look at each element in order.

Choosing a can for a distillation cube

The feasibility of improving the distiller largely depends on what container is used. So, it is better to use an ordinary Soviet-CIS aluminum can as the basis of a simple distiller, at the same time, if you purchase a new or used flask on the Internet from food grade stainless steel of European or Chinese design, then you can think about creating a mash or distillation column.

The volume of such containers ranges from 10 to 100 liters, but the most popular are moonshine stills made from flasks of 25, 40 and 50 liters. It is also important, if the choice falls on an aluminum product, to pay attention to the integrity and general state protective coating.

The first determines whether toxic aluminum oxides will get into the moonshine, and the second determines how long the container will last.

Converting the can is not a difficult task, since it is already equipped with a convenient and airtight locking system. There are a few technological holes left to make.

- The first is necessary to remove hot steam. For this purpose, it is better to use a fitting and seal the gap with a gasket made of food-grade silicone or heat-resistant non-toxic sealant.

- The second hole is needed to install a thermometer. It is better to use a bimetallic device, having previously installed a sealing sleeve in the hole and sealed it using the same method as the fitting.

Hoses

For a simpler unit based on an aluminum flask, the best solution would be steam lines made of food-grade silicone, but for a more solid design based on a stainless can, it’s worth thinking about steam lines made of the appropriate material.

Although their production will result in high costs, the durability and reliability of such a system is much higher, especially if it is planned to install a reflux condenser or column.

In general, the selection of hoses for a moonshine still should be based on the power of the system, which determines their optimal length and internal diameter, so that the operating pressure is maintained and no zones of high hydraulic resistance are created.

Fridge

For a simple distiller, there are two alternatives - and a direct-flow one, but even in this case you need to rely on the power of the entire system, because the higher it is, the higher the likelihood of condensate plugs forming in the coil.

For models based on a flask with a volume of more than 25 liters, it is better to choose a straight-flow, although you can also choose a coil, but provided that the tube cross-section has a significant diameter.

If you plan to install a reflux condenser, mash or distillation column, then you don’t have to choose - only direct-flow. This is due both to its higher power and efficiency, and to stable operation that is not subject to condensation plugs, which is very important for such units.

To a simple unit for distilling moonshine based on an aluminum flask, an excellent addition that improves the quality of the distillate would be a bubbler, or better yet, a bubbler-steamer combination.

In this case, the first one performs “rough” and the second one “soft” steam purification, while the steamer can be simultaneously used for maceration of moonshine - saturating the alcohol with the aroma and flavor of herbs, fruits and other ingredients. To do this, you just need to put them inside.

A more serious design of the unit involves installation on a flask or, which, by the way, can be made at home if materials are available, but this will require detailed familiarization with their features, as well as the essence of the rectification process.

In this case, you need to think about the heating source, since for high-quality separation of a multicomponent mixture you need smooth heating and precise adjustment, and there are three options.

- First, but not the best - this is;

- second– this is the installation of heating elements, they have a smoother adjustment, but do not guarantee that the mash will not burn;

- third– this is the best, but also the most expensive solution.

Other types of moonshine stills

Among homemade household units, one of the most common options is.

The fact is that this container is essentially a high-quality ready-made distillation cube that requires minor modifications, which significantly simplifies the process of manufacturing the distiller.

This device is not only an excellent distillation cube, but also has a very convenient, correct, similar to heating elements and easily adjustable heating system.

For those who need to distill moonshine in the absence of tap water, the model of a non-flowing moonshine still will be of interest.

It uses a large capacity to cool the coil, which is why the water has time to cool due to environment, without the influx of new cold.

And finally, the most controversial device is one in which the liquid goes through a double “evaporation-condensation” cycle, rather than a single one, as in a conventional distiller.

A “classic” moonshine still made from an aluminum flask is a simple and affordable solution that meets all the basic requirements of moonshine brewing, especially since it is now possible to purchase a can made from food-grade stainless steel, which is suitable for creating advanced distillation systems such as a mash or distillation column.

In this case, the issue of expensive work on the production of a distillation cube is resolved, for which you still need to look for qualified specialists and good materials.

In addition, the guaranteed high, factory-made quality of the product is also a significant plus; otherwise, the efficiency of such a unit depends on the chosen configuration of the refrigerator and cleaning units.

Purchasing a large volume moonshine still will not be cheap. If you want to save money or find an application with your own skillful hands, you can create a moonshine still from a milk flask yourself. These food containers are suitable for a still with minor modifications. How to make a moonshine still from a flask?

Buying a new or used metal food flask is easy. There is a wide selection of these containers on the market of various capacities, from 20 to 100 liters. All of them are equipped with hermetically sealed lids with gaskets that can withstand high temperatures. Having decided on the volume of the future distillation cube, you need to resolve the issue of the material from which it is made.

Aluminum

Aluminum flasks were produced in the Soviet Union and are still produced in the CIS countries and China. They are inexpensive, easy to rework, and suitable for high temperatures. There is an opinion that aluminum, in combination with high temperature and alcohol vapors, oxidizes and affects the quality of the final drink, and can even be harmful to health. But there is still no final verdict on this issue. And aluminum containers are widely used in home brewing.

Stainless steel

Stainless steel cans are considered safe for health. This material definitely does not affect the quality of the produced moonshine. Such a container costs more than aluminum, but there are no problems with purchasing it either. The containers are produced in European countries and China. When buying a stainless steel flask, it is better not to pay attention to offers comparable in price to aluminum ones. Stainless steel is clearly more expensive, and a cheap option should be alarming.

Rework sequence

Converting a can into a distillation cube involves drilling holes for connecting pipes and additional devices. Their diameters depend on the connected elements of the moonshine still. Therefore, it is better to purchase them before remaking the flask. The lids of the milk flasks are wide and there is enough space for all the necessary drilling.

- A hole is made in the lid of the can for the outlet steam line. If the latter is metal, then it is better to cut a fitting into the lid and connect through it. For silicone steam lines, you can immediately insert the fitting into the lid, but it is also possible to attach it through the fitting.

- A strong recommendation is to install a safety valve on the lid to release steam. It can be removed from the pressure cooker, or can be purchased separately at the store. Without such a valve, operation of the device is unsafe.

- Another hole is drilled in the lid to install a thermometer.

All parts inserted into the finished holes are fastened on the inside of the cover with union nuts through silicone gaskets.

A still from a flask with a volume of up to 20 liters can be heated over an open fire. But it is better to do this using a steam generator or built-in electric heaters. And for large cans this is actually a prerequisite. In addition, a large distillation cube must be equipped with a tap for convenient drainage of the mash.

- The hole for the drain valve is drilled in the side wall of the flask.

- And also a fitting for the hose from the steam generator is cut into the side wall at a height of two to three centimeters from the bottom of the flask.

- If you plan to heat the mash with electric heating elements, then for each of them, one or two holes are also drilled at a height of two to three centimeters. The number of the latter depends on the type of electric heater being inserted. The latter must be reliably isolated from the can body.

Moonshine with snack

The finished distillation cube from the flask is connected via a steam line to a refrigerator with a coil. Possibly with the additional installation of a steam steamer or.

Advantages and disadvantages

The advantages of making moonshine stills from flasks are the following:

- This is a ready-made sealed container designed for preparing and storing food. The material complies with the standards in this area.

- The flask is easy to carry and has a wide neck, through which it is easy to pour mash and clean it after use.

- Conversion into a distillation cube is not particularly difficult.

The disadvantages include the following:

- Usually the bottom of the flask has a rim around the perimeter. This design practically eliminates the heating of the flask on the electric stove. But for other heating methods this is not a hindrance.

- The need to apply effort and materials for rework. Those who do not have a penchant for such activities should consider purchasing a ready-made device. But if you want to work independently, then this minus turns into a plus.

So, it is quite possible to make a moonshine still from a flask, and with your own hands. Heating is allowed over an open fire, but it is better to use a steam generator or electric heater.